The welder called and said our toolbox was ready. We jumped in the locksmith truck and jammed tunes as we cruised over to scoop it up; our minds racing.

The welder called and said our toolbox was ready. We jumped in the locksmith truck and jammed tunes as we cruised over to scoop it up; our minds racing. Did we have the bolts, drill bits, washers, and nylon nuts for it? We need paint. Happy happy joy joy. Then, we went to work. We fit and mounted the aluminum plate on the tricycle. It took a while to figure out where to place the toolbox so it was stable and we had enough room in the rear for our rear end. If the toolbox was mounted too close to the seat, it would be uncomfortable, at best. We needed room to pedal and have the room to really dig in if we had to bust a move.

Did we have the bolts, drill bits, washers, and nylon nuts for it? We need paint. Happy happy joy joy. Then, we went to work. We fit and mounted the aluminum plate on the tricycle. It took a while to figure out where to place the toolbox so it was stable and we had enough room in the rear for our rear end. If the toolbox was mounted too close to the seat, it would be uncomfortable, at best. We needed room to pedal and have the room to really dig in if we had to bust a move. We are confident that we are going need to reinforce the 4 mounting points with either a strap, or a bottom strut. It’s solid and secure, but it needs to be able to withstand our locksmith techs jumping it. You know they’re going try to jump it. Give them a piece of plywood and a few cinder blocks and they’re all stuntmen. One bad jump and the bolts shear. Not a good scenario. It needed to be ready for their wear and tear, devil-may-care approach to traffic. The same reason we wrap the locksmith technician phones in these ‘indestructible’ cases. Indestructible? They’ll put that claim to the test. Don’t tease them.

We are confident that we are going need to reinforce the 4 mounting points with either a strap, or a bottom strut. It’s solid and secure, but it needs to be able to withstand our locksmith techs jumping it. You know they’re going try to jump it. Give them a piece of plywood and a few cinder blocks and they’re all stuntmen. One bad jump and the bolts shear. Not a good scenario. It needed to be ready for their wear and tear, devil-may-care approach to traffic. The same reason we wrap the locksmith technician phones in these ‘indestructible’ cases. Indestructible? They’ll put that claim to the test. Don’t tease them. These are the new ape hangers. It makes the ride nicer not having to stoop over the bike. The old handlebars were silver. I like the black better.

These are the new ape hangers. It makes the ride nicer not having to stoop over the bike. The old handlebars were silver. I like the black better.

The box mounted nicely and now we needed to install the drawer for the key duplicator. The mounts for it have been welded into the toolbox and the drawer sliders were next.

The box mounted nicely and now we needed to install the drawer for the key duplicator. The mounts for it have been welded into the toolbox and the drawer sliders were next.

Weston, you look tired. Are you sleeping and drilling again? Weird.

Weston, you look tired. Are you sleeping and drilling again? Weird. It went in well. Then we took it all apart, for paint. Stay tuned as we primer, paint, and decal our new locksmith beach trike, Big Red.

It went in well. Then we took it all apart, for paint. Stay tuned as we primer, paint, and decal our new locksmith beach trike, Big Red.

Month: May 2015

Pacific Beach Locksmith 2015 Spring Locksmith Build Wrap Up

We are excited to complete our 2015 Spring Locksmith Build in time for summer action. It was a solid build and went really well. Here is Weston putting the final touches on the electrical system battery and inverter. Dan is going to town on organizing the keys and Weston is hamming it up for the camera. Weston spearheaded this project hard but we wouldn’t have had it done in such a timely manner without Josh and Dan having our backs and supporting the Dup-A-Key team. They really stepped up and made sure the service calls got done while we pieced it all together. Go team!

Dan is going to town on organizing the keys and Weston is hamming it up for the camera. Weston spearheaded this project hard but we wouldn’t have had it done in such a timely manner without Josh and Dan having our backs and supporting the Dup-A-Key team. They really stepped up and made sure the service calls got done while we pieced it all together. Go team! Here is Tim Steen putting the decals on the truck. He did a wonderful job on our truck, making sure the spacing was correct and the seams clean.

Here is Tim Steen putting the decals on the truck. He did a wonderful job on our truck, making sure the spacing was correct and the seams clean.

Summer is here. Our new Pacific Beach locksmith truck is online and school finals are wrapping up. The fuse has been lit and summer is just beyond tomorrow’s big storm. Stay tuned for our wacky summer adventures!

Summer is here. Our new Pacific Beach locksmith truck is online and school finals are wrapping up. The fuse has been lit and summer is just beyond tomorrow’s big storm. Stay tuned for our wacky summer adventures!

Pacific Beach Locksmith Eco Trike Key Duplicator Platform Framing and Dup-A-Key Locksmith Vinyl Decal Mockup

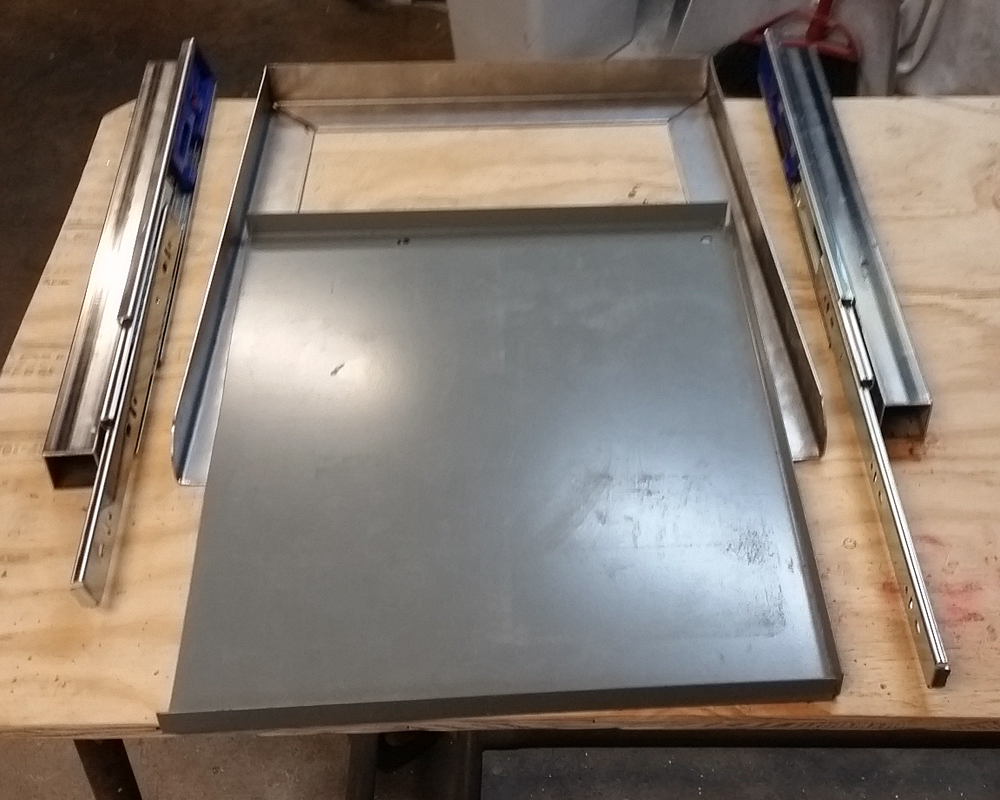

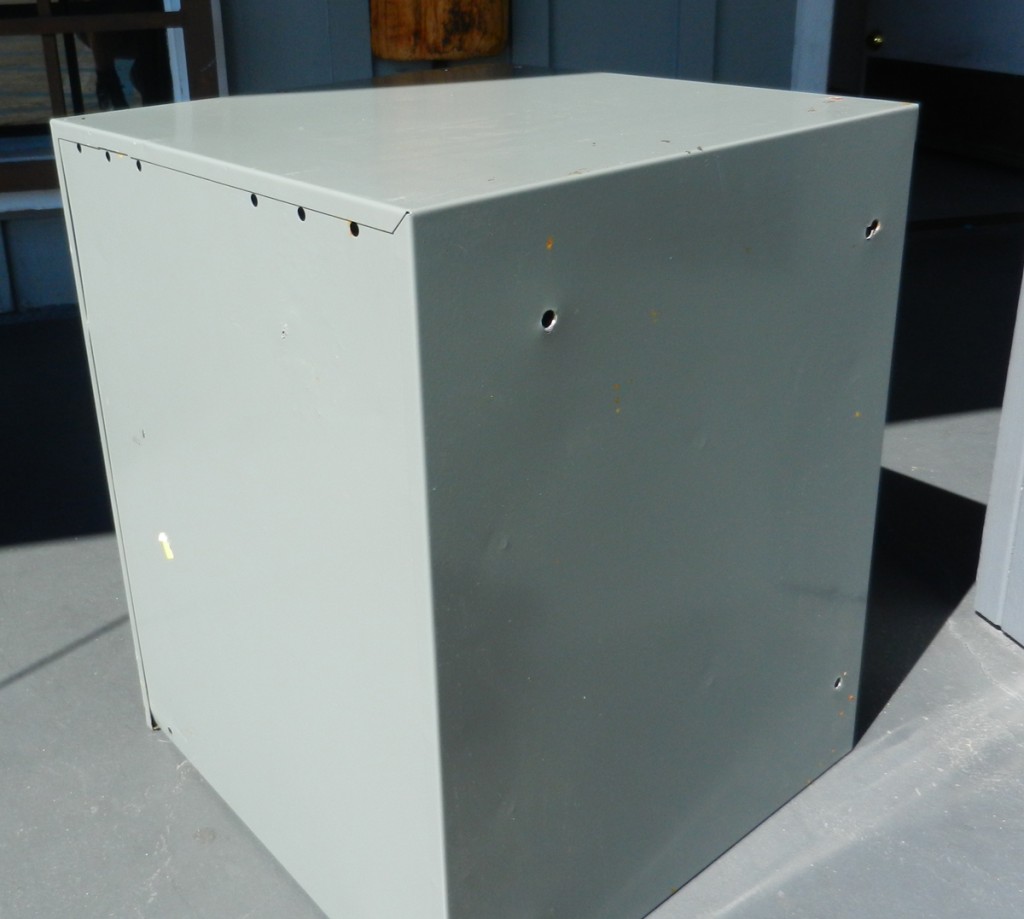

This is the inside of the toolbox for Big Red before we sent it off to the welder. We need to have the holes filled and weld the mounts for the slide out key duplicator platform. The bottom of the toolbox is made of aluminum and must be cut and fitted to Big Red. Weston bought aluminum instead of steel for the bottom of the toolbox to reduce the weight. Steel is typically two and and half times more dense than aluminum. Hopefully, it will also reduce some corrosion. It will be painted white, so I doubt that it will matter much. These are the pieces of the sliding platform that the key duplicator wil be on.

These are the pieces of the sliding platform that the key duplicator wil be on. Weston did a nice job cutting and bending the frame for the platform.

Weston did a nice job cutting and bending the frame for the platform.  Here’s a close up of the angle. Ready for our welder’s steady hand.

Here’s a close up of the angle. Ready for our welder’s steady hand.  Here is the platform as it should look inside the toolbox. The key duplicator platform was cut from the only shelf that came with this Adrian Steel toolbox. It’s like waiting for Christmas morning on this toolbox build. We’ve been naughty, too. Hmm.

Here is the platform as it should look inside the toolbox. The key duplicator platform was cut from the only shelf that came with this Adrian Steel toolbox. It’s like waiting for Christmas morning on this toolbox build. We’ve been naughty, too. Hmm.

We had the vinyl decals cut when we cut the NV locksmith truck decals. Here is a mockup of what it should look like in a week or so. We’re digging it.

We had the vinyl decals cut when we cut the NV locksmith truck decals. Here is a mockup of what it should look like in a week or so. We’re digging it.

Stay tuned as our Pacific Beach locksmith trike helps us overcome our beach traffic and parking hurdles. We might get a nice set of calf muscles, and tone those glutes in the process. As long as we’re not driving around in circles all day, looking for a parking spot, we’ll be stoked. We got some medium sized ape hangers for it (not in above photo). It’s easier on the posture, not bending over.

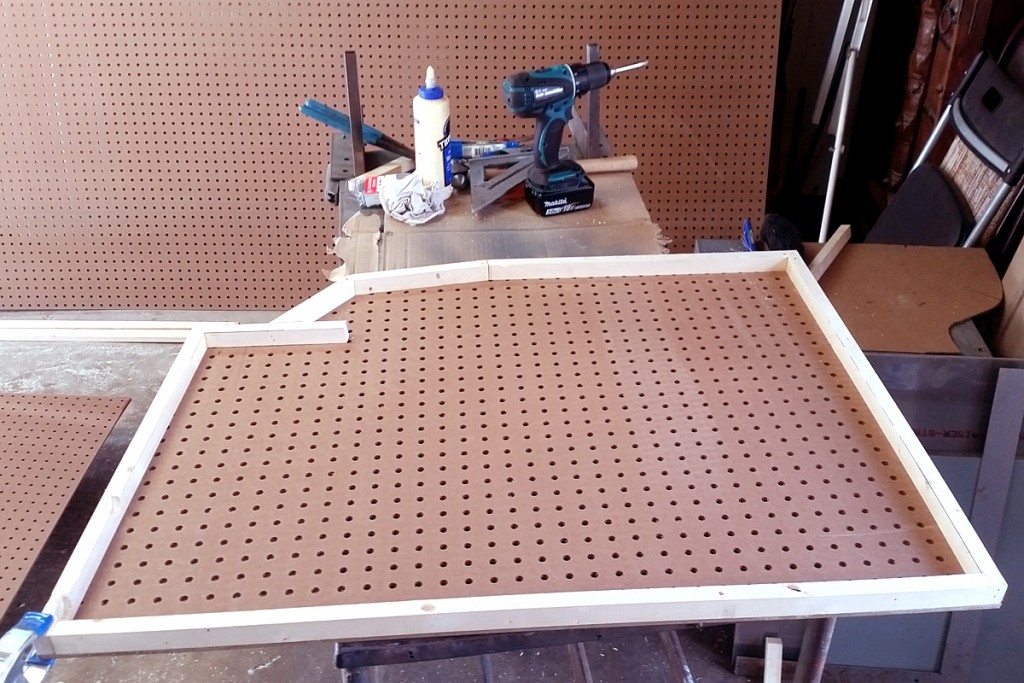

Pacific Beach Locksmith Installs Pegboards for San Diego Mobile Locksmith Truck

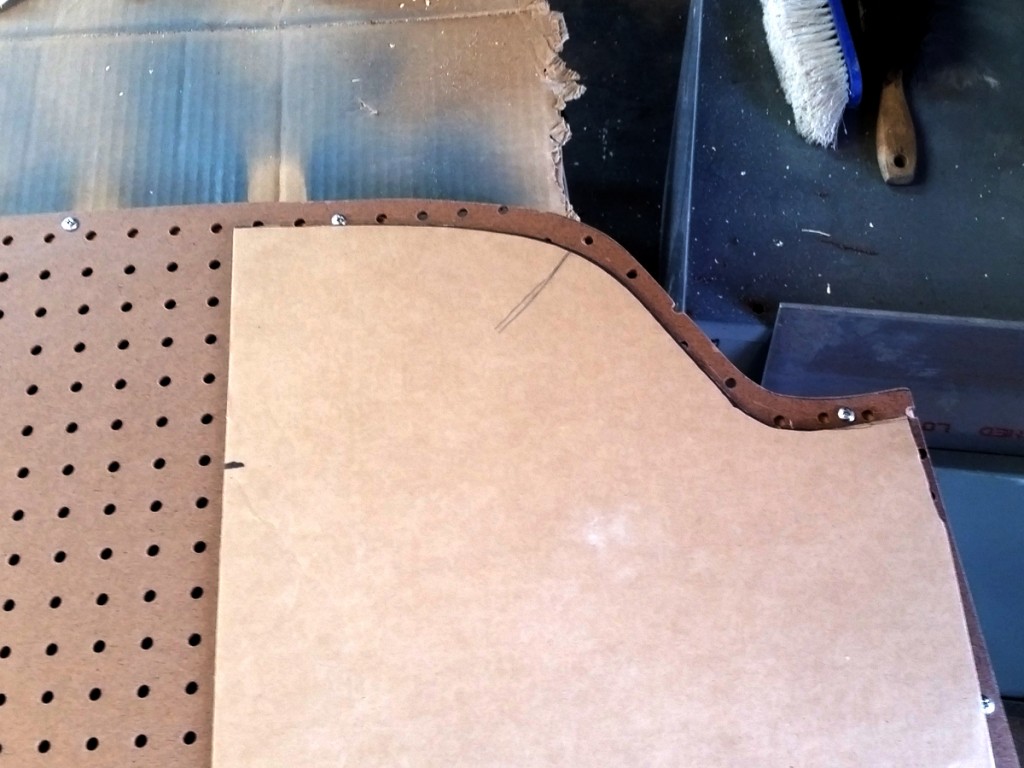

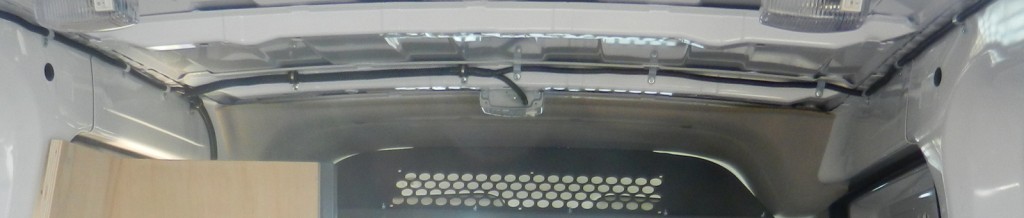

This is where the pegboards need to go for the car keys and house keys in our Nissan NV subcompact cargo van. First, Weston makes a template for the curves on the the roof line so it’s nice and tight.

First, Weston makes a template for the curves on the the roof line so it’s nice and tight.  After the roof line is traced, he jigsaws the pegboard, and frames the back.

After the roof line is traced, he jigsaws the pegboard, and frames the back. Easier said than done.

Easier said than done.

Umm.. OK, show-off. That’s enough. We opted to put bags between the peg boards where the partition slanted back instead dropping straight down and having a gap behind the board and a loss of space. Glad we did. The bags fit well there and we thought about putting lockout tools there but it seemed a waste of space. Two pegboards aren’t going be enough.

Umm.. OK, show-off. That’s enough. We opted to put bags between the peg boards where the partition slanted back instead dropping straight down and having a gap behind the board and a loss of space. Glad we did. The bags fit well there and we thought about putting lockout tools there but it seemed a waste of space. Two pegboards aren’t going be enough. Here is the pegboard above the workbench. Now there is a lot of room for hanging keys. That wire hanging is for the fan but we moved the fan to the corner of this side door. It’s a better fit for the truck there and boosts the cross flow of air pretty good. It reminds me of the old fans in the school buses for the bus driver.

Here is the pegboard above the workbench. Now there is a lot of room for hanging keys. That wire hanging is for the fan but we moved the fan to the corner of this side door. It’s a better fit for the truck there and boosts the cross flow of air pretty good. It reminds me of the old fans in the school buses for the bus driver. Weston has done it again. Well played, sir. It’s time to install the key machines, hang the keys, stock the car ignitions, mount the first aid kit, new tool bag, organize the lock hardware, and put bags behind the machines.

Weston has done it again. Well played, sir. It’s time to install the key machines, hang the keys, stock the car ignitions, mount the first aid kit, new tool bag, organize the lock hardware, and put bags behind the machines. Best vehicle build ever, besides his Scout II build, or his VW Beetle build. Ok. Ok. Best Locksmith Truck build ever. This was a fun one, and we are happy that we gained two inches between the benches from what we had in the old trucks. We cut it in tight. Stay tuned for decals and equipment install. We have to sell ‘El Burro’. We’re not buying new tires for it, again.

Best vehicle build ever, besides his Scout II build, or his VW Beetle build. Ok. Ok. Best Locksmith Truck build ever. This was a fun one, and we are happy that we gained two inches between the benches from what we had in the old trucks. We cut it in tight. Stay tuned for decals and equipment install. We have to sell ‘El Burro’. We’re not buying new tires for it, again.

Pacific Beach Locksmiths Prep to Install the Toolbox to the Big Red Eco Trike Rapid Response Locksmith Unit

So we have completed the NV of SD Nissan locksmith truck and have now set our sights on completing our Eco Friendly Rapid Response Trike – Big Red

So, it has some holes that need to be repaired and a set of mounts welded on the inside of the box to install the slider brackets for the key duplicator. It is off to the welder on Cass Street for some touchup work.

Here is Weston propping up the box so you can see what it will look like once it is installed. We’re going to paint it white and the decals for it are ready to go. So exciting to have this ride on line. It is going to make our locksmith rekeys, car lockouts, and lockpick runs around the beach a lot easier on the boys. Hope our welder gets it back to us this week. Stay tuned for the our rapid response locksmith trike that can circumvent beach traffic and doesn’t need a parking space or gasoline.  Heres a side view. I’m glad Big Red is a 6 speed. A quick estimate puts the extra weight load at 85 – 90 lbs. Looks like we should all be in excellent shape by the end of the summer. Yaa! Summer is here!

Heres a side view. I’m glad Big Red is a 6 speed. A quick estimate puts the extra weight load at 85 – 90 lbs. Looks like we should all be in excellent shape by the end of the summer. Yaa! Summer is here!

Pacific Beach Locksmiths Install Electrical in New Nissan San Diego Locksmith Truck

So the shipment for the Nissan electrical arrived and we went to town on wiring up the locksmith truck. We went the solenoid setup over the diode setup for the battery charging system. We had the diode system in ‘El Burro’ . I remember one of the guys at Broadway Electrical saying they were “not that great”. He was right. It was problematic and had to be replaced, after frying itself out. Didn’t do wonders for the battery either. Those guys at Broadway Electrical, in Lemon Grove, are great. They really know their stuff. They ran a short down for us once. We searched for a couple days. It kept blowing the fuse and we couldn’t find it. They ran it down. Good service and knowledgeable. Solenoid all the way for us. We have the same charging setup in the ‘The Stickman’ and it works great. Not one problem.

So the shipment for the Nissan electrical arrived and we went to town on wiring up the locksmith truck. We went the solenoid setup over the diode setup for the battery charging system. We had the diode system in ‘El Burro’ . I remember one of the guys at Broadway Electrical saying they were “not that great”. He was right. It was problematic and had to be replaced, after frying itself out. Didn’t do wonders for the battery either. Those guys at Broadway Electrical, in Lemon Grove, are great. They really know their stuff. They ran a short down for us once. We searched for a couple days. It kept blowing the fuse and we couldn’t find it. They ran it down. Good service and knowledgeable. Solenoid all the way for us. We have the same charging setup in the ‘The Stickman’ and it works great. Not one problem.

Running the lines for the lights and the fan went pretty quick. Nice and tidy. Here is Weston, checking out his handiwork at the fuse box. Solid marine grade setup he found on the web. Perfect for our ocean air environment.

So then comes running the main electrical wire to the engine compartment.

So then comes running the main electrical wire to the engine compartment.

This can only really be properly done by removing the seat. You almost always have to remove the seats on a good build. You don’t want wires sticking out or chaffing on a bad run. I know your wire comes in a thick plastic coating, but you have to hide and protect your electrical system. It’s more fragile than you would think.

This can only really be properly done by removing the seat. You almost always have to remove the seats on a good build. You don’t want wires sticking out or chaffing on a bad run. I know your wire comes in a thick plastic coating, but you have to hide and protect your electrical system. It’s more fragile than you would think.

Next I run the wire into the center console and then through an existing hole under the dashboard. I look rad in those Oakleys. I managed not to scratch them throughout the run. My eyes felt super relaxed the whole time. Hooray Oakley! Made in USA. USA! USA! Bringing back the chant!

Next I run the wire into the center console and then through an existing hole under the dashboard. I look rad in those Oakleys. I managed not to scratch them throughout the run. My eyes felt super relaxed the whole time. Hooray Oakley! Made in USA. USA! USA! Bringing back the chant!  This is me, licking the emergency brake handle. That’s a pretty hair bun.

This is me, licking the emergency brake handle. That’s a pretty hair bun.

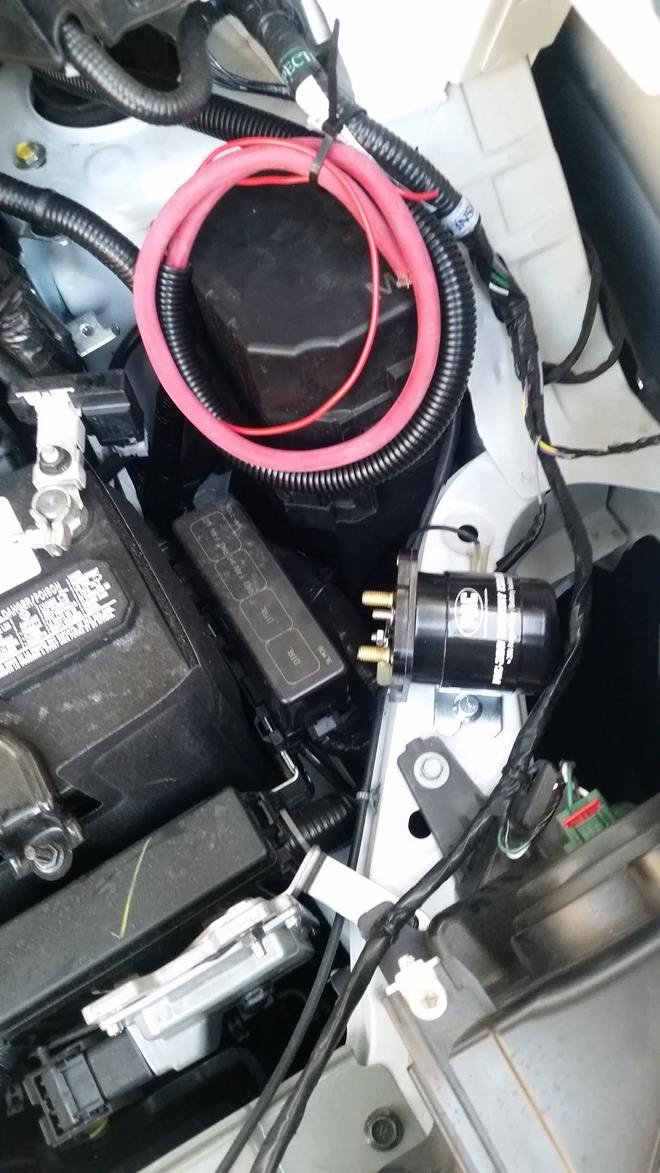

So the wire has been run through to the engine comparment and there is a lot of room in the front engine compartment. That made mounting the solenoid a piece of cake. There is a nice spot on the body near the battery.

So the wire has been run through to the engine comparment and there is a lot of room in the front engine compartment. That made mounting the solenoid a piece of cake. There is a nice spot on the body near the battery.

Here is the two battery charging system all hooked up and with the inline fuses for both batteries installed. Overall, a tidy little install. Good job, Wes.